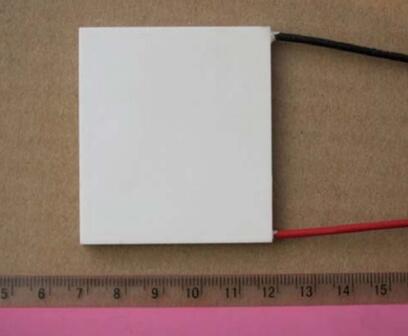

TEC modules are used to regulate and stabilize the temperature of the target object. TEC modules can cool down or heat up the target object according to the direction of the current going through the two terminals of TEC modules.

How to select a proper TEC module? First the maximum temperature difference is a major parameter in selecting TEC modules. Commonly, the temperature difference is between 60ºC and 72 ºC. Higher temperature difference can be achieved by choosing a two stage or multiple stage TEC modules. Second, to achieve high efficiency. Minimizing thermal resistance between the TEC plate surface and heat sink surface and between the TEC plate and the target object surface is a good method. It's best to solder the plates of TEC modules to the heat sink and to the target object, or use thermal paste between the TEC plates and the heat sink and the target object. At last, a good grasp of the applications and an understanding for heat transfer are also needed in selecting TEC modules and designing a TEC system.

Peltier modules can work with heat sink, TEC controller and thermistors to form different temperature control systems.

For technical data and more types of Peltier modules, please refer to:

http://www.analogtechnologies.com/tec-module.html

For more and various types of electronic products, please visit our homepage at: